- 日本の漆の歴史と伝統 -

The History and the Characteristics of

Urushi Lacquerware 漆器

Deep and shiny luster of black or red, sometimes adorned with a gold leaf or mother-of-pearl inlay, you may have encountered beautifully decorated urushi lacquered chests or boxes or tableware in museums or as in historical treasures from the East.

Japanese Lacquer Chest [ Flower, bird and animal design in maki-e lacquer and mother-of-pearl inlay]

(花樹鳥獣蒔絵螺鈿櫃)Edo period, 17th century, Tokyo National Museum

"The entire surface is sprinkled with sharkskin grains, and the pattern is expressed by raden (mother-of-pearl inlay) and hira-makie (flat gold sprinkled on lacquer). However, the term "sharkskin" is actually a term used to refer to Stingray skin. Stingray skin comes from Southeast Asia and was imported to Japan in large quantities during the Edo period (1603-1867). Lacquerware made from ray skin was actively exported through the Dutch East India Company in the mid-17th century."

From the Official Explanation (translated by Kogei Styling)

Source:ColBase(https://colbase.nich.go.jp/) , © National Institutes for Cultural Heritage

Japanese lacquerware, referred to as "japan" in the old days, was introduced to the West by the Portuguese in the 16th century and widely spread in the 17th century by the Dutch East India Company, and immediately enthralled royalty and nobility.

[Important cultural property] Portable Shrine Depicting Birds and Flowers in Maki-e Lacquer

(花鳥蒔絵螺鈿聖龕) Azuchi-Momoyama period, 16th century, Kyushu National Museum

(The Christianity Painting is made in Europe and placed in the shrine afterwards)

From the Official Explanation (portion);

".....This shrine recently returned to Japan from Europe, and is currently the largest of its kind in the nation. It is topped by a sloping karahafu gable, and has double doors in front that open to reveal the sacred painting inside. Both the outer and inner faces of both doors are decorated extensively in gold and silver maki-e lacquer and mother-of-pearl inlay. Each face features geometric medallions framing arabesque, bird, and flower motifs. It houses an oil painting on a bronze plaque, depicting the Virgin Mary watching over a sleeping baby Jesus, with Saint Joseph on her right. To her left is St. John, holding a cross in his right hand and placing his left index finger over his mouth. The Latin inscription at the bottom of the painting reads, “Ego dormio et cor meum vigilat” (I sleep, but my mind is awake). This work, which combines excellent lacquer techniques with lavish decorations, serves as a fine example of nanban lacquerware, which in itself paints a picture of international exchange during the European Age of Discovery."

For millennia, the resin of the urushi tree, known as urushi (漆), has been employed as a protective coating or adhesive in the creation of sacred ceremonial ornaments, artistic masterpieces, and utilitarian objects. The oldest known urushi lacquered artifacts discovered in Japan (Kakinoshima B ruins in Hokkaido) date back to 7000 BC during the Jomon period, representing the most ancient urushi lacquer objects found to date.

The allure of urushi lacquer extends beyond its captivating beauty and luster. As one of the most resilient natural lacquers, urushi is derived from the resin of the urushi tree (rhus verniciflua), predominantly found in East Asia. The extraction process harnesses the tree's innate vitality, as the resin is produced for self-healing when the tree is damaged. Consequently, urushi boasts numerous exceptional qualities, including a unique humidity-induced drying process, impressive adhesion to various substances, and remarkable hardness and durability once dried. Furthermore, urushi lacquer is resistant to water, acids, alkali, alcohol, and heat, and exhibits antibacterial and insect-repelling properties, which were well-known to ancient civilizations.

Throughout history, urushi lacquer has been applied to numerous significant objects, including religious and ceremonial ornaments, Buddha statues, armor, wooden structures, as well as temple and shrine ceilings and floors. Additionally, it has been used for tableware and furniture, immersing the Japanese in a world surrounded by the beauty of urushi lacquer. Even today, traditional Japanese values can be observed in time-honored wedding ceremonies.

Traditional Japanese wedding ceremony. The bride is having sake before the god.

Sake cup (sakazuki) and sake vessel are lacquerware.

photo from 写真AC taken by yagitoki

Traditionally, urushi lacquerware sakazuki (sake cup) is used.

photo from 写真AC taken by kkphoto

To create lacquerware tableware, urushi is typically applied to wood materials, and occasionally to natural materials like cloth or paper, which are molded into shape. The meticulous process involves multiple stages of urushi lacquer coating, drying, and polishing, resulting in a durable and visually stunning surface that defines Japanese lacquerware. For instance, Wajima lacquerware (produced in Wajima City, Ishikawa Prefecture) undergoes between 75 to 130 handcrafted processes, making it one of Japan's most durable lacquerwares.

To create lacquerware tableware, urushi is typically applied to wood materials, and occasionally to natural materials like cloth or paper, which are molded into shape. The meticulous process involves multiple stages of urushi lacquer coating, drying, and polishing, resulting in a durable and visually stunning surface that defines Japanese lacquerware. For instance, Wajima lacquerware (produced in Wajima City, Ishikawa Prefecture) undergoes between 75 to 130 handcrafted processes, making it one of Japan's most durable lacquerwares.

(A comprehensive guide to Japanese lacquerware can be found here: http://www.nihonkogeikai.or.jp/old/TEBIKI-E/3.html)

Decorative techniques such as maki-e (sprinkled application of gold or silver powder/plate) or raden (mother-of-pearl inlay) are used with urushi as an adhesive. These urushi decorating techniques reached their pinnacle of beauty and sophistication during the Edo period in the 18th century.

Today, we are fortunate to enjoy the fruits of the exceptional craftsmanship that has been cultivated through the long and illustrious history of urushi in our daily lives. We invite you to experience the elegance, refinement, and time-honored tradition embodied in Japanese lacquerware.

What is Urushi? 漆

<Note> To describe urushi lacquer botanically accurately, we have revised our terminology from "sap" to "resin" of the urushi tree. Although both sap and resin originate from plants, the sap is a watery liquid that circulates through a plant's vascular system, while the resin is a more viscous substance secreted by certain plants and trees, typically to protect or seal wounds. Botanically, using the term "resin" is the correct way to describe what urushi is.(Mar.2023)

Urushi lacquer, derived from the natural resin of the urushi tree, is a remarkable and versatile material. The tree produces the resin as a self-healing mechanism when it is damaged, endowing it with numerous protective qualities. There are no synthetic alternatives for urushi or urushiol (the main component of urushi) available.

Remarkably, only about 200 ml (one cup) of urushi resin can be collected from a 10 to15-year-old urushi tree. After the resin is harvested, the tree is often cut down in Japan, making way for a new tree to be planted.

The cultivation of numerous urushi trees enables the resin to be collected, gathered, and refined for use as urushi lacquer. The process of resin collection is a skilled and time-honored manual technique, carried out by the increasingly rare urushi resin collector.

In terms of material composition, Japanese raw urushi is made up of urushiol (60–65 wt%), water (25–30 wt%), plant gums (5–7 wt%), and enzymatic laccase (0.2 wt%). Urushiol is essentially an organic oil, and its content varies depending on factors such as tree location, tapping techniques, and the tree's growth stage. A higher urushiol content typically indicates better quality urushi lacquer.

After filtering out wood scraps and contaminants, raw urushi is used to adhere and protect materials like wood. It is believed that urushi provides the most protection when used in its raw state. Fuki-urushi (applied and wiped urushi) employs this raw urushi.

Refining raw urushi involves two major processes: stirring/grinding (called Nayashi) and evaporating and concentrating the water content from an initial 30% down to around 3 wt% (called Kurome). The Nayashi, which is the stirring/grinding process, will refine the size of the large plant gums contained and make the surface roughness of the urushi lacquer coating finer and smoother. The purpose of the Kurome process is to evaporate water content to have more transparency, but the most important point of this evaporation process is the control of the temperature. You should never kill the enzymatic laccase which will die above 50 degrees centigrade. If the enzymatic laccase is dead the urushi lacquer will not solidify. So if you are successful in these processes, you will increase the gloss and transparency of the urushi which will result in a higher quality lacquer for lacquerware. The color of this pure natural urushi lacquer raw or refined is brown.

The coloring of the lacquer is done by adding various natural substances. The most common and widely perceived color of the Japanese urushi lacquer may be glossy purely black color. In Japan, the pure black color is often mentioned as "Urushi Black" depicting true black color. And there is a reason. In order to make a black urushi lacquer, iron hydroxide is added to raw urushi and the right chemical reaction between iron hydroxide and the raw urushi will create the true black color. It normally takes a day or more for this reaction to happen. This chemical reaction to create the black color is totally unique to urushi lacquer. That is why urushi was so important and used to create truly black-colored items in Japan. In such a way. the black urushi lacquer is different from other colors. In other color cases, the color of the additive itself (such as red cinnabar pigment) creates the color along with the brownish urushi color. And the same with the other colors.

Similar to color additives, to enhance the aesthetic and functional properties of urushi and achieve desired effects, various natural substances are added to the refined urushi. Examples include diatomite for increased durability and abrasion resistance, and rice or tofu (soybean protein) for improved viscosity and adhesion. Urushi lacquer is unique in a way that it accepts and disperses many different various materials very well.

The hardening process of urushi lacquer is unique due to its natural origins. In the presence of high humidity (70-80% RH) and warm temperatures (20-25°C), the oxidation of urushiol catalyzed by laccase causes urushiol to polymerize, forming a hard, plastic-like substance. This results in a highly durable and water, acid, alkali, alcohol, and heat-resistant film. Moreover, urushi's strong adhesive properties enable it to bond effectively with a wide range of materials, including wood, metal, ceramics, leather (deer skin), and stone. Furthermore, urushi boasts long-lasting antibacterial and insect-repelling qualities even after application and drying.

Urushi's only vulnerability is to UV exposure. However, despite this limitation, urushi lacquer is widely regarded as the finest natural coating material in existence.

Urushi tree after urushi resin has been collected (Ibaragi, Japan)

Cut down urushi tree after urushi resin has been collected for the season of five months (Ibaragi, Japan)

Traditional urushi refining process "Kurome" by hand under the sun.

It is to evaporate water content from about 30% to 3 wt%.

Natural urushi lacquer for base coat use.

(Courtesy of Wajimaya Zen-ni )

The intermediate polishing process of a rectangular plate

(Courtesy of Wajimaya Zen-ni )

The middle coating process of a small bowl

(Courtesy of Wajimaya Zen-ni )

Cultural Recognition of Lacquerwork In Japan

漆 芸

Lacquerwork as an Important

Intangible Cultural Properties

The Japanese government acknowledges and designates the nation's most significant cultural properties, both tangible and intangible, as "National Treasures," "Important Cultural Properties," or "Important Intangible Cultural Properties." These represent Japan's most highly esteemed historical and cultural assets.

(For a definitional overview of the Cultural Properties designated by the Japanese government, please visit:

https://www.bunka.go.jp/english/policy/cultural_properties/introduction/overview/)

Toiletry Case with Cart Wheels in Stream (片輪車蒔絵螺鈿手箱) 12th Century “National Treasure”

(Tokyo National Museum)

Numerous Japanese lacquerware artifacts throughout history have been designated as National Treasures or Important Cultural Properties, such as the "Toiletry Case with Cart Wheels in Stream" (Tokyo National Museum) from the Heian period (12th century).

The techniques and skills required to create Japanese lacquerware are passed down through generations and are recognized as Important Intangible Cultural Properties (IICP) within the Craft Techniques category.

Lacquerwork is one of the seven areas of IICP Craft Techniques, which also include Ceramics, Textile Weaving and Dyeing, Metalwork, Woodwork and Bamboo Work, Doll Making, and Papermaking.

As of April 2019, there are 16 "Collective" or "Group" recognitions and 59 "Individual" recognitions within the IICP Craft Techniques category. Individual recognitions are granted to master artisans, who are commonly referred to as "Living National Treasures."

Out of the 59 individual Living National Treasures in the Craft Techniques domain, 11 specialize in lacquerwork, illustrating the high regard and respect for these skilled artisans. Four of these 11 lacquerwork Living National Treasures are associated with Wajima or Wajima-nuri.

Among the 16 Collective or Group IICP Craft Techniques recognitions, two are designated for lacquerwork. Wajima-nuri (lacquerwork) has held this Collective IICP recognition since 1977, and Tsugaru-nuri (lacquerwork) was added in 2017. These are the only two recognized lacquerwork techniques out of more than 23 lacquerware-producing areas in Japan.

These distinctions demonstrate the exceptional skill and value attributed to Wajima lacquerwork, which has earned widespread respect and admiration within the Japanese lacquerware community.

Urushi, A Valuable Asset 漆

Natural Urushi

Urushi resin, being a natural resin, possesses remarkable protective properties due to its role in healing the tree when it is damaged. Only around 200 ml (one cup) of urushi resin can be collected from a single urushi tree that is 10 to 15 years old. After resin collection, the tree is typically cut down to make way for a new tree to be planted.

Urushi resin collection in Japan

The entire process of urushi resin collection is carried out by specially trained and skilled craftsmen, not only in Japan but also in China and Southeast Asia. Each tree is unique, and there is no alternative method for extracting the resin from these individual trees.

A prime example of traditional urushi resin collection in Japan can be seen in the work of Mr. Gaku Hirai, a trained urushi resin collector. Mr. Hirai collects urushi resin from urushi trees in Hitachi-Ohmiya City, Ibaraki Prefecture, demonstrating the expertise and dedication required to sustain this ancient craft.

Urushi tree being groove cut using special urushi kanna (knife)

The season for urushi resin collection typically spans from late May to the end of October or early November, depending on the region. During this season, resin is collected every 4 to 5 days, allowing the urushi tree time to recover from the damage caused by the groove cuts and regenerate its urushi resin supply. This careful harvesting process ensures the tree's vitality and promotes continuous resin production throughout the season.

Urushi tree being groove cut slightly slanted for efficient collection of urushi resin

The depth of the groove is a crucial factor in producing high-quality urushi. If the groove is too shallow, the resin will not flow adequately, and if it is too deep, the vitality of the urushi tree may be compromised. Striking the right balance is essential for both ensuring the tree's health and obtaining the desired resin yield. Skilled urushi resin collectors possess the expertise to make precise cuts that maximize resin production without causing undue harm to the tree.

Urushi resin will ooze out a couple of minutes after the cut

Urushi resin collection using special urushi spatula

Every drop of urushi resin is collected swiftly into the urushi bucket

Urushi is tapped by carving the bark of the urushi tree with horizontal long groove and let the tree yield clear to milky-white resin. It takes at least 10 years, preferably 15 years for an urushi tree to grow big enough to be tapped.

A skilled urushi collector will tap the urushi trees from June to October and collect drops of the resin one by one. Normally each urushi tree being tapped will have three days before next taps are made during the season and normally the tree will be cut down after that one season harvest of the urushi resin. The urushi tree yields only about 100 to 200 grams of raw urushi resin in its whole lifetime, which makes it a very precious and expensive substance.

The urushi could only be collected by the hands of a skilled urushi collector. There is no machinery to collect the urushi resin. The required skill, knowledge, and decision making to collect fine urushi resin are very high and complex. Since each tree is different, you need to understand how the condition of each tree is.

To tap the urushi, you need to take many things into account; the angle of each trunk of the tree, the direction of the sun, the thickness of the bark on each position you tap, how vigor the tree is due to the recent damage you gave, recent weather and so on. If you groove too deep and too long, you will kill the tree and your yield will go down, if you groove too little, you may not kill the tree but the results are the same. If your tapping angle of the groove is not right, you lose the resin.

Four days is the mimimum interval for tapping a tree. Urushi tree needs three days to produce the urushi. So the urushi collector will come to the tree every four days. The skilled collector may tap about 60 to 100 trees per day, depending on the places. So in theory, you need at least 60 x 4 = 240 new trees per season for a collector to efficiently collect the urushi resin in the season. The collector will collect in total 240(trees) x 150(grams/tree) = 36 (kgs) of raw urushi per season of five months full-time work without weekends. (tapping is not done on a rainy day) You need at least 10 years for an urushi tree before being tapped. Therefore, you constantly need at least 240 x 10 years = 2400 urushi trees for the urushi collector to sustain his work.

Traditionally urushi trees have been cultivated in the steepest mountains where the farming cannot be made. (Recent urushi tree cultivation are made on moderate hills for preservation purpose) Urushi tree yields the best resin in the highest season in summer. Therefore Urushi collection had been one of the toughest occupations in Japan.

Facts about the Urushi lacquer used in Japan

The production volume of Japanese raw natural urushi lacquer in Japan was quite limited in recent years, with only 1,845 kgs in 2018 and 1,045 kgs in 2013. This accounted for merely 4.9% in 2018 and 2.6% in 2013 of the total raw natural urushi lacquer consumed in Japan, which was 37,724 kgs in 2018 and 40,542 kgs in 2013. The remaining 95.1% in 2018 and 97.4% in 2013 was imported raw natural urushi lacquer. The main importing countries in 2013 were China (89.2%), Thailand (5.7%), and Myanmar (2.5%), which together provided 97.4% of the raw natural urushi lacquer consumed in Japan. These numbers are derived from government statistics. It is believed that the import of raw natural urushi lacquer from China dates back to the Edo period (1603 - 1868).

Chinese natural urushi lacquer has a similar material composition to Japanese natural urushi lacquer, but it is said that Japanese urushi lacquer provides a higher gloss, luster, and hardness when applied, dried, and polished, compared to Chinese urushi lacquer. As a result, the aesthetic beauty of the finished product may differ. On the other hand, the cost of Chinese natural urushi lacquer is only one-tenth to one-fifth of the Japanese counterpart. Consequently, even the highest-quality Japanese lacquerware typically uses Japanese natural urushi lacquer only for the top-coat, while the bottom-coat and middle-coat utilize Chinese natural urushi lacquer, where the aesthetic quality of the lacquer is not a significant concern.

By now, you can appreciate the value of urushi and the efforts behind creating genuine lacquerware. We are confident that your interest in Japanese lacquerware will contribute to preserving the tradition of urushi collection in Asia.

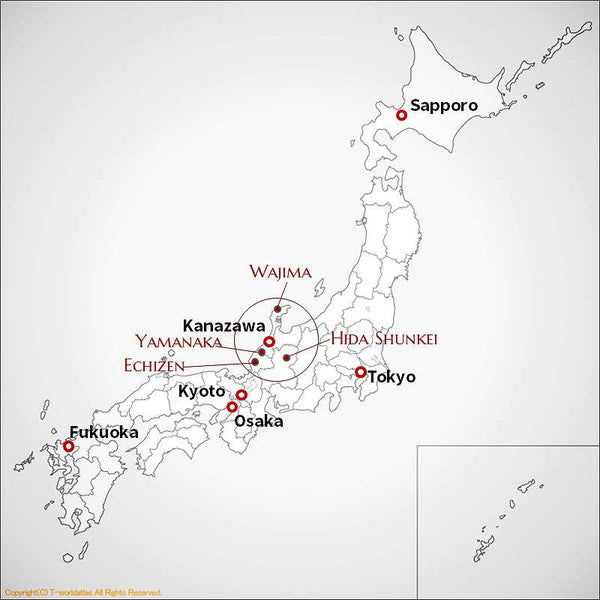

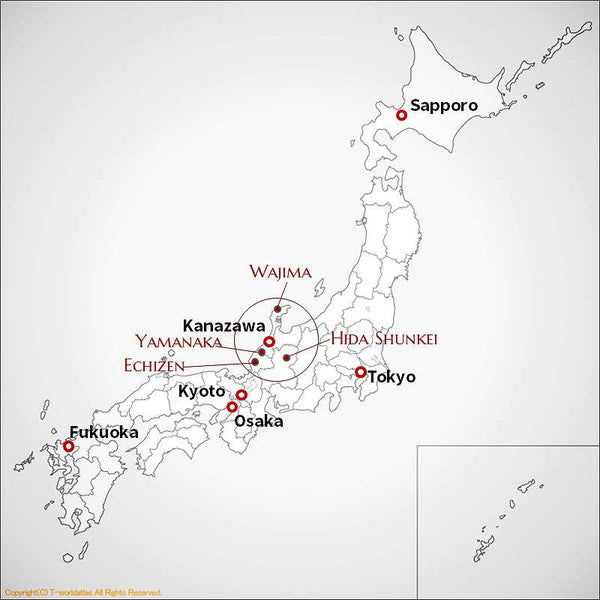

Areas in Japan that Our Lacquerwares are Made

Our Area Brands and Locations in Japan

- Wajima

- Wajima-city Ishikawa

- Yamanaka

- Kaga-city Ishikawa

- Hida Shunkei

- Takayama-city Gifu

- Echizen

- Sabae-city Fukui

Currently, the products that we carry are from the Hokuriku (Central Northern Areas of Honshu Main Island)